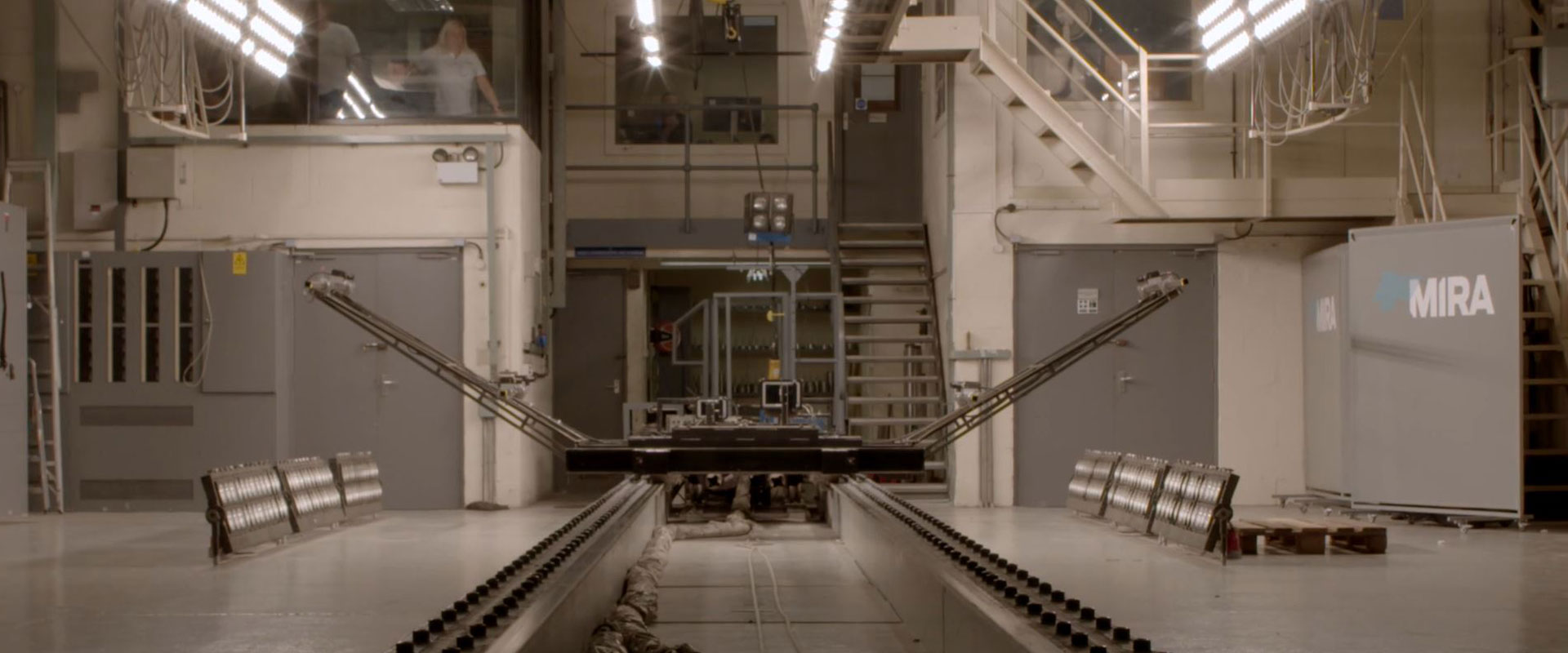

HyGe Laboratory

The HyGe sled facility is a key part of HORIBA MIRA’s safety offering.

It provides safety-related testing services to numerous worldwide customers across an ever-increasing range of sectors.

HyGe Laboratory

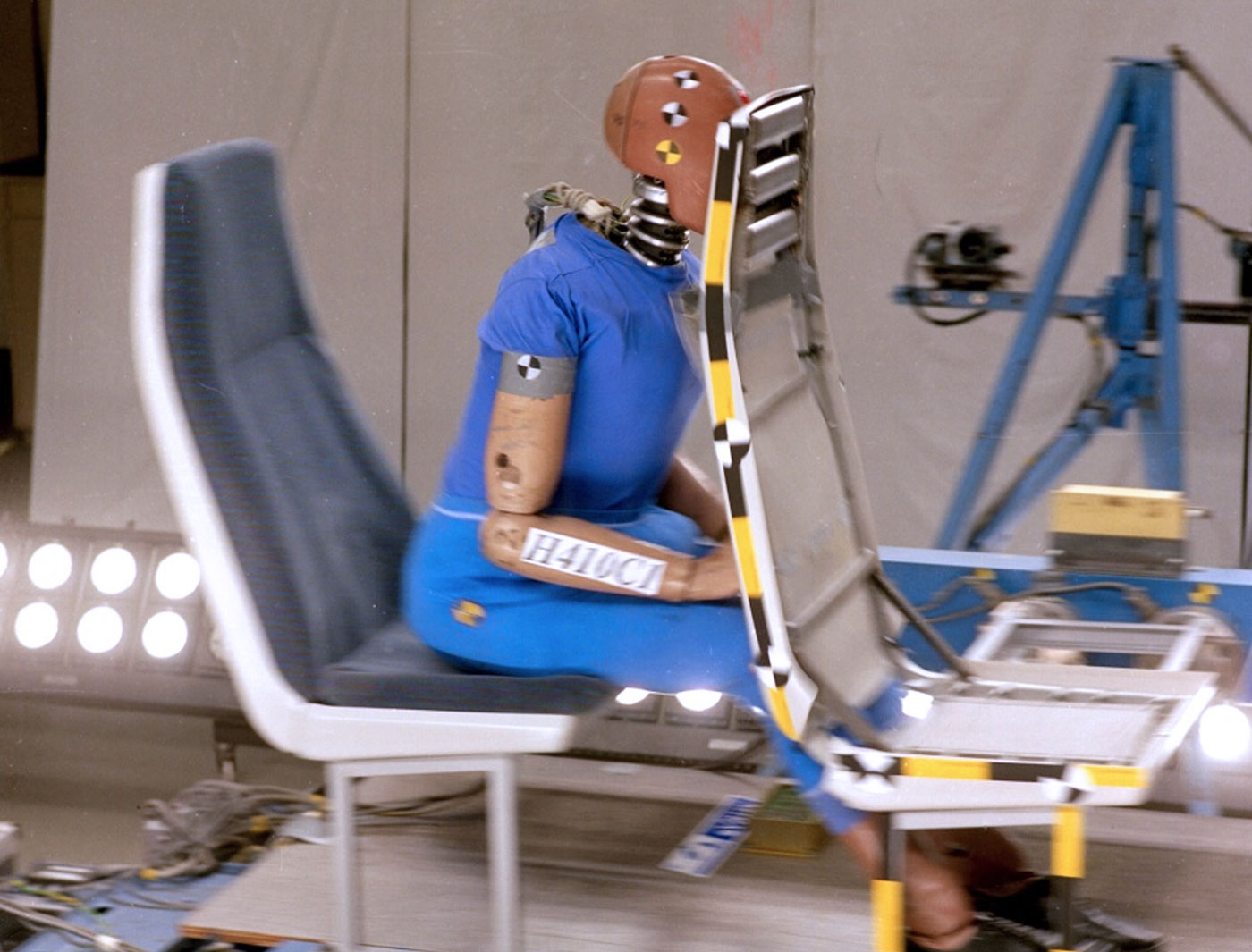

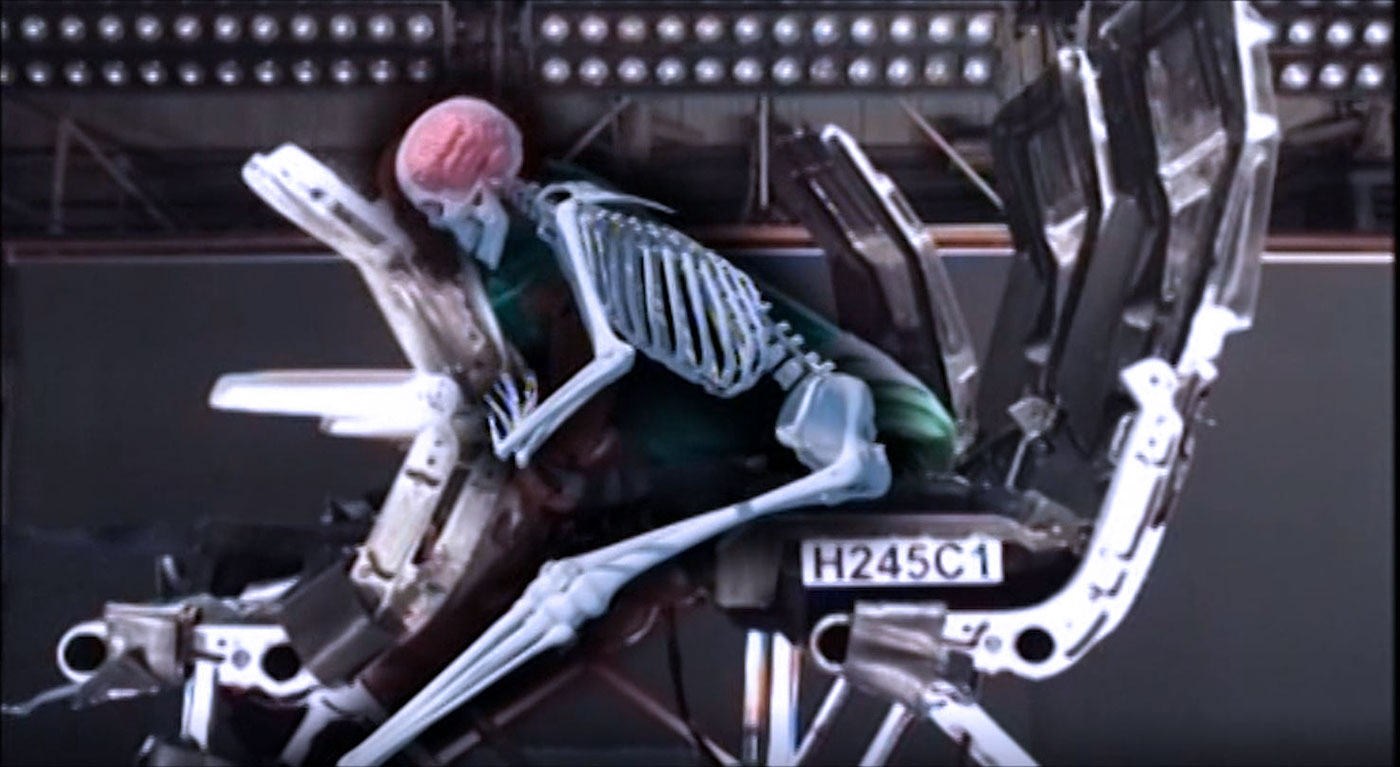

Footage provided by Panasonic Mobile Solutions Business Division Europe.

The propulsion system of the HyGe facility provides up to 100 ‘g’ of reverse acceleration and has been designed in such a way to allow HORIBA MIRA’s safety engineers to accurately replicate legislative profiles in many sectors, whilst still allowing for bespoke reverse acceleration profiles to be simulated with very short lead times.

The HyGe sled facility is a key part of HORIBA MIRA’s safety capabilities. It provides safety-related testing services to numerous worldwide customers across an ever-increasing range of sectors.

The facility is capable of delivering multiple tests each day and has fast turn-a-round times between tests as it benefits from a high capacity recharging system, multiple sled bodies which are detachable from the HyGe sled allowing different tests to be prepared, tested and decommissioned all in parallel.

Each sled body has been designed to deliver optimum performance for each sector, with HORIBA MIRA having sled bodies to meet the needs of the aero, rail and automotive sectors as well as general sled used for bespoke testing and other test types.

In addition, HORIBA MIRA has designed and introduced its own active side impact system (M-SIS). M-SIS is a sled body able to replicate actual vehicle side impact intrusion whilst decelerating, proving to be an effective and cost-efficient occupant restraint development tool.

The facility performance is strengthened by the level of staff expertise supporting it. Leading UK industry experts, dedicated and highly experienced crash engineers and skilled technicians with fabrication workshops ensure that tests get performed to scope, even if the product or its fitment being tested needs a little rework.

Feature

Specification

Max vehicle mass

5kg – 5,000kg (11lbs – 11000lbs)

Max vehicle dimensions

3.3m (10.5ft) long and 2.2m (7.2ft) high

Max acceleration

6g – 70g (dependent on mass)

Impact timings

10ms – 200ms / 2.5m (8ft) stroke

Temperature range

Ambient with heating and air conditioning typically 19°C to 26°C

Number of tests per day (typically)

2 – 8 (depending on complexity of test)

Number of interchangeable sleds

4

High Speed – High Definition Cameras

12 cameras, Full HD, 1000fps

Instrumentation

160 channels

This facility has achieved the ISO 17025 accreditation for the competence of testing and calibration laboratories