Vehicle Thermal Energy Optimisation Suite

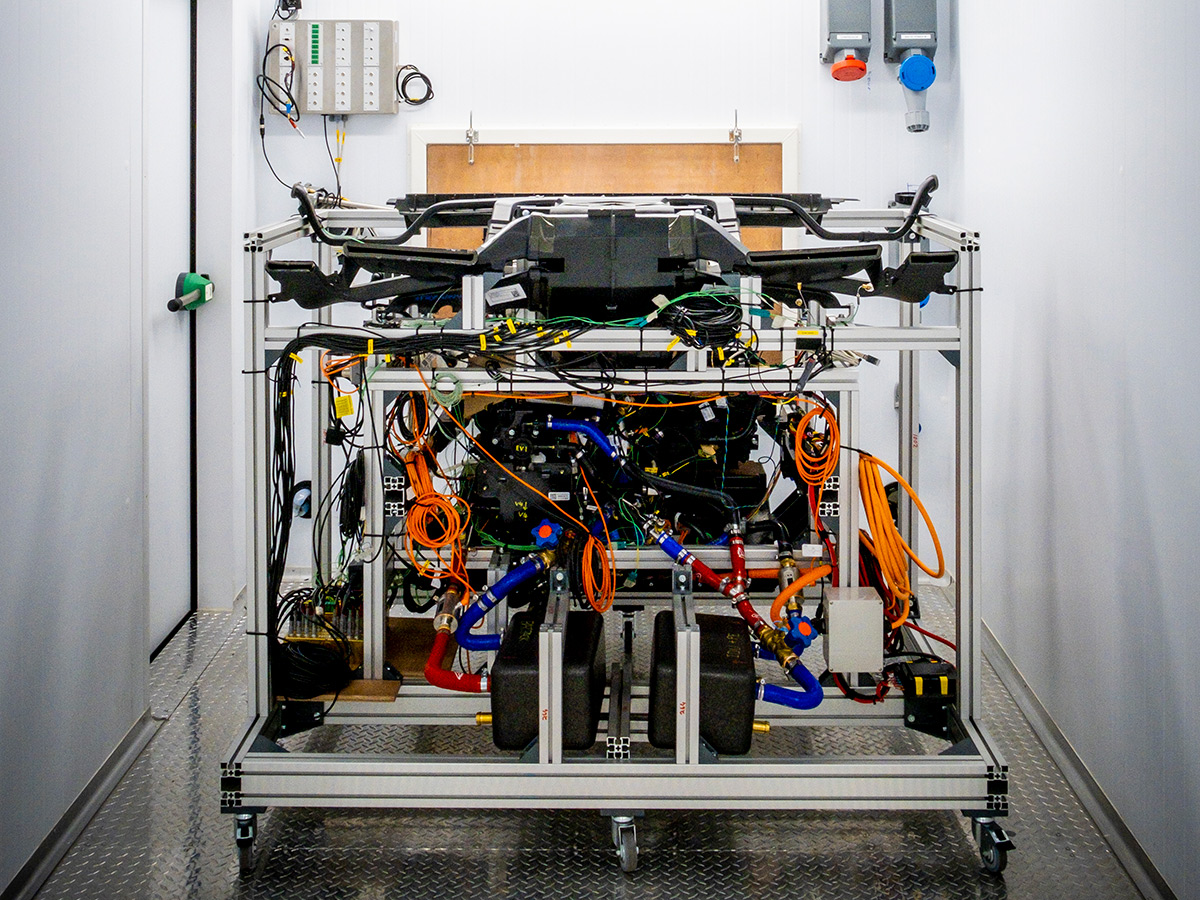

We have revolutionised vehicle thermal energy management with our cutting-edge Vehicle Thermal Energy Optimisation Suite.

The suite offers a range of services, including target setting, benchmarking, design verification plan (DVP) development, CAE model-based design, and system development. Used in conjunction with our Climatic Wind Tunnels, the suite also supports vehicle validation.

Our holistic approach accelerates thermal system development within the development cycle, resulting in minimised risks, reduced time to market, and significant cost savings compared to traditional methods.

Integrating the thermal suite with our Powertrain Propulsion Centre optimises heat pump development, leveraging pre-existing chilling plant capacity for enhanced efficiency. This, in turn, significantly reduces facility setup costs, making the Vehicle Thermal Energy Optimisation Suite a key component of our comprehensive vehicle thermal energy management service.

The VTEOS provides a critical new toolset to develop and validate:

- Variety of HVAC system architectures including Heat pump systems

- Battery thermal management integration

- Powertrain thermal management integration

- Novel refrigerant performance

System Performance Characterisation

- Multi-supplier system integration

- Component trade off / swapping components against each other

- Model Correlation

- Refrigeration fluid comparison

- Capacity and system efficiency (COP)

Traditional and Heat Pump System Development

- Architecture definition

- Controls and Software development & optimisation

- Modes of operation

- Performance improvement

- TXV / EXV Tuning

- De-icing strategies

Typical validation tests

- Used for a wide range of component and systems development

- Charge determination

- IHX sizing

- Oil in Circulation (Criticalfor warranty agreements)

- VDA/SAE performance characterisation

- TXV & eTXVtuning

- COP optimisation

- Control development

- Component characterisation

- Refrigerant comparison & development

- Electric Compressor & chiller loads

- Compressor torque